The samples of liquid crystal to be measured in the laboratory, can be found in three different approaches. Liquid crystal cells, Free-standing films and flat jets. The research group has made an effort to master and improve each of the methodologies for positioning and exploring the sample. In the following, the three approaches are explained.

Liquid crystal cells

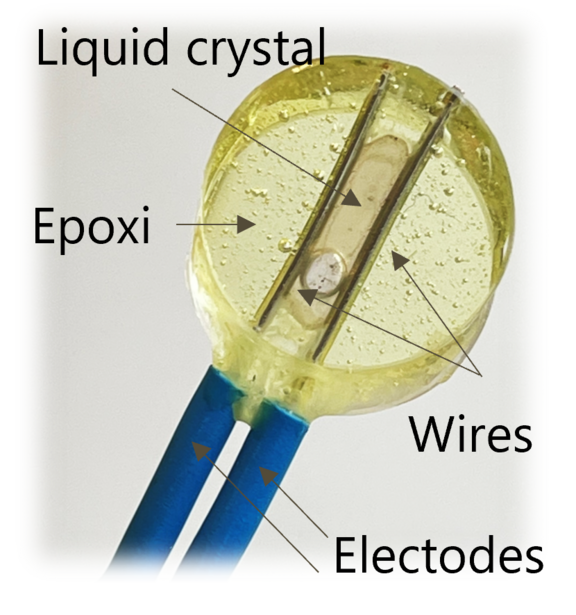

A cell is a container used to hold a liquid crystal (LC) sample. It is typically made from materials that are transparent to the radiation being used, such as quartz or silica, which allows the radiation to pass through without interfering with the measurements. The cell consists of two parallel glass plates, maintained at a constant distance using spacers of defined thickness ranging from a few micrometers to hundreds of micrometers

To minimize defects and ensure proper functionality, the glass surfaces undergo a thorough cleaning procedure. Since the LC needs to align in a specific direction on the glass substrate, the inner surfaces of the cell are treated with a special polymer that imposes either homeotropic (perpendicular) or planar (parallel) alignment. This treatment can be applied through spin coating or by dipping the substrates into the polymer solution.

If no polymer is used for alignment, two metallic wire can be integrated into the cell design, and AC voltages of up to 1kV can be applied to control the alignment. Once the alignment solution is implemented, the cell is assembled using UV-curable glue. The LC is then introduced and the cell is sealed to prevent leakage. The LC occupies the space between the two glass plates.

Finally, the cell needs to be characterized in terms of its structure and alignment, and this is typically done using a polarizing microscope.

Free-standing LC films

Free-standing films offer several advantages over traditional liquid crystal (LC) cells, such as the ability to create substrate-free static samples with reduced thickness. The formation of free-standing films is possible due to surface tension in smectic LC mesophases. However, they also present challenges, including maintaining mechanical stability and precise alignment control. In a freely suspended film, the air-surface interface influences the alignment of the surface director similarly to a treated glass substrate, but with a weaker effect. The alignment is maintained over a certain layer depth, referred to as the correlation length.

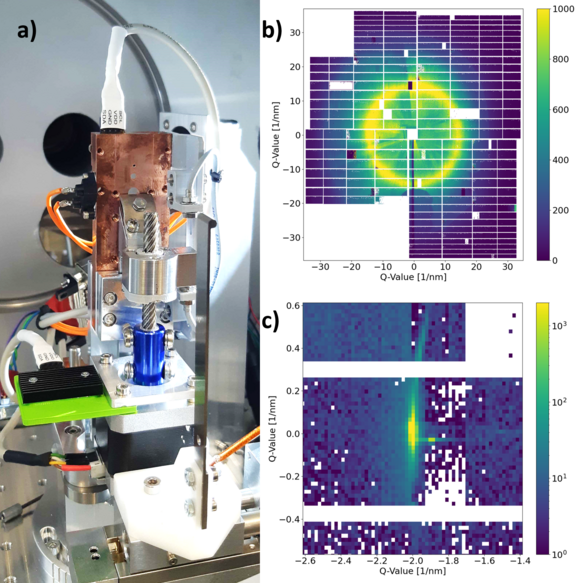

The design of the liquid crystal holder was inspired by the linear target insertion mechanism of the Ohio State University Scarlet Laser Facility [1,2], which enabled film formation in a vacuum at high repetition rates (10 Hz). The holder consists of a wiper that moves vertically across a circular opening in a copper frame. The wiper is guided by a bridge, allowing for variation in the force with which it is pressed against the frame. Openings with diameters of a few millimeters are used for various applications, enabling control over film thickness. These openings are beveled with a sharp edge, ensuring that the LC is formed in a fixed position inside the bevel. Temperature control is used for precise thickness control, achieved by heating the frame with resistors and cooling with Peltier elements. Additionally, an automatic LC release mechanism was integrated, enabling remote control of the system.

[1] Poole, P.L., et al., Liquid crystal films as on-demand, variable thickness (50-5000 nm) targets for intense lasers. Physics of Plasmas, 2014. 21(6).

[2] Poole, P.L., et al., Moderate repetition rate ultra-intense laser targets and optics using variable thickness liquid crystal films. Applied Physics Letters, 2016. 109(15).

Flat jet device

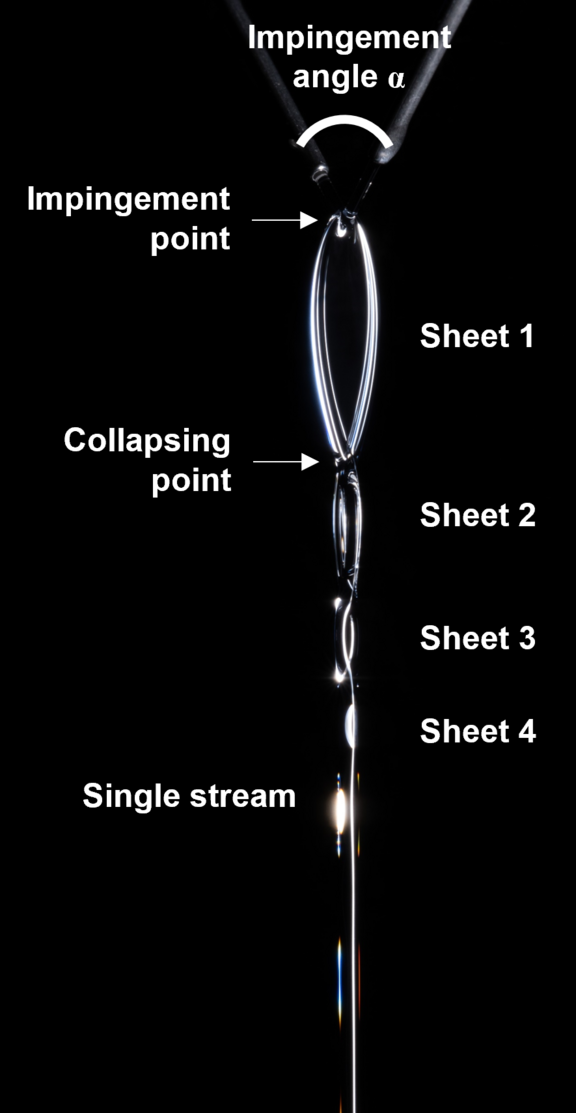

A primary concern when using high-powered lasers on static samples, such as cells or free-standing films, is the risk of damage due to the low damage threshold of these materials. For high harmonic generation spectroscopy in liquid crystal (LC) samples, which requires intensities around 10 TW/cm², we have opted for a flat jet device for sample delivery, a well established solution in liquid spectroscopy, benefiting from the flowing properties of liquid crystals. This device is ideal for creating a controlled, uniform, and reproducible liquid flow, which is essential for applications needing a thin, flat stream. To generate this flat surface, two laminar jets converge, forming a stable fluid chain composed of micrometer-thick sheets that are oriented perpendicular to each other and then merge into a single stream [1-2]. As a result of the flowing delivery system, each laser pulse interacts with a fresh sample, reducing the risk of thermal buildup and localized overheating, which could otherwise damage the sample. Additionally, the thin liquid layer promotes efficient heat dissipation, increasing the damage threshold and allowing for more powerful laser applications without causing excessive harm to the sample.

However, delivering liquid crystals (LCs) with flat jets presents challenges, as LCs have distinct flow properties compared to standard liquids. Unlike Newtonian fluids, whose viscosity remains constant under varying shear rates, LCs exhibit behavior influenced by the coupling between molecular alignment and flow. The viscosity of LCs is lowest when the molecules align with the flow and highest when they are perpendicular to it. Furthermore, LCs can experience increased viscosity under shear stress, resulting from molecular rearrangements. These unique characteristics must be carefully considered when designing recirculating lines, pumping systems, and pressurized nozzles for LC delivery.

In our group, we have designed and implemented a temperature-controlled recirculating flat-jet system tailored specifically for LC delivery. This system offers a reliable solution for delivering liquid crystals in a given mesophase in spectroscopic applications, maintaining precise control over the sample flow. We have thoroughly characterized the flat-jet system, evaluating factors such as its stability, the rate of sample refreshment, the thickness of the liquid sheets, and the alignment of liquid crystal molecules in both isotropic and nematic phases [3].

[1] T. T. Luu, et al., Nat. Commun. 9, 1 208

[2] M. Ekimova et al., Struct. Dyn. 2, 054301, 2015

[3] M. L. Murillo-Sánchez et al., Rev. Sci. Instrum. 95.10, 2024